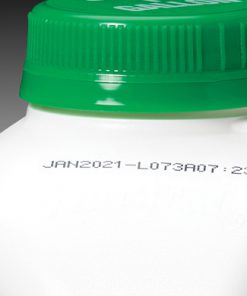

Laser Marking

- 100-Watt fiber laser marking high contrast at high speed

- Quality marking on robust plastic and metal materials

- Maximum single line speed: 600m/min (1968 ft/min)

Laser Marking

- 50-Watt fiber laser marking high contrast at high speed

- Quality marking on robust plastic and metal materials

- Maximum single line speed: 440m/min (1440 ft/min)

Laser Marking

- 7230 10-Watt and 7330 20-Watt fiber lasers for marking permanent quality codes on robust, high-density materials

- Light, compact and adaptable laser marking solutions offering high-speed marking, with complex data, easy operability and industry-leading integration capabilities

- Designed for demanding production schedules in the Parts-Marking, Food, Beverage, Consumer Packaged Goods (CPG) and Pharmaceutical industries

Thermal Inkjet

- Purpose-built MEK cartridge for adhesion on a variety of non-porous substrates

- Cartridge Readiness SystemTM helps provide consistent code quality

- Code Assurance features minimize potential coding mistakes

- Intuitive tablet-like 5'' touchscreen controller with CLARiTY™ interface used in other Videojet technologies

- Simple cassette design holds 700m maximum of ribbon to allow for longer runs, and offers a safer and easier way to replenish ribbon, with minimal impact to production

- Code assurance comes as standard when using templates created by CLARiSOFT™ or VideojetConnect Design software

- Available with Bluetooth®* capability, allowing printer control via the Videojet 6230 App on an Android device**, rather than a HMI.

- Videojet iAssure™ intelligent technology which automatically detects common print defects, helping to reduce unwanted waste or reworked product

- Intelligent Motion™ technology removes the need for compressed air and associated costs and downtime, maximizing consistent print quality and printhead life

- Quick change printhead and minimal wear parts reduce the time production is interrupted when replacements are required

- Modular design that easily integrates into your production line and includes the option to mount the power supply and connection hub in the host machine control cabinet

High Performance CO2

- 10W CO2 laser marking with CLARiTY™ touchscreen controller, engineered to minimize coding mistakes

- High performance delivers crisp codes on moderate line speed applications

- Line set-up wizard aids fast product changeovers, maximizing uptime

- Virtually no maintenance and limited consumables

High Performance CO2

- 30W CO2 laser marking with CLARiTY™ touchscreen controller, engineered to minimize coding mistakes

- Extended mark speed capability of up to 150,000 products per hour, ideal for high line speed applications

- High speed variable coding and data buffering, combined with the largest mark window in the industry, help increase throughput and performance

- Integration features for fast install and set-up