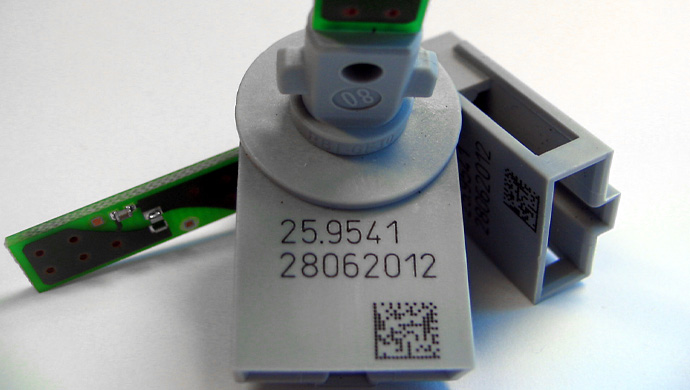

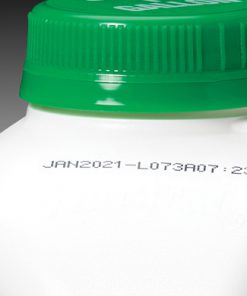

Printing on Plastic and Rubber Parts

Industrial Coding and Marking Solutions for Plastic and Rubber Parts Printing

Plastic and rubber parts vary in composition, color and elasticity. They include an array of substrates including polypropylene, polyurethanes, acrylonitrile butadiene styrene, and sometimes include slick plasticizers and other challenging components.

With over 40 years of ink development experience, Videojet offers a range of high adhesion inks for even the most challenging substrates. Colored and pigmented inks provide high contrast codes on darker surfaces for easier readability, important for both internal manufacturing controls as well as external traceability. Videojet laser marking systems offer permanent marks for traceability throughout the product life cycle. A wide range of laser accessories including lenses and beam turning units help simplify line integration and maximize laser performance.

Continuous InkJet Printers Laser Marking PrintersLASER MARKING Printers for printing on Plastic AND RUBBER PARTS

High Performance CO2

- 10W CO2 laser marking with CLARiTY™ touchscreen controller, engineered to minimize coding mistakes

- High performance delivers crisp codes on moderate line speed applications

- Line set-up wizard aids fast product changeovers, maximizing uptime

- Virtually no maintenance and limited consumables

High Performance CO2

- 30W CO2 laser marking with CLARiTY™ touchscreen controller, engineered to minimize coding mistakes

- Extended mark speed capability of up to 150,000 products per hour, ideal for high line speed applications

- High speed variable coding and data buffering, combined with the largest mark window in the industry, help increase throughput and performance

- Integration features for fast install and set-up

High Performance CO2

- 60W CO2 laser marking with optional CLARiTY™ touchscreen controller, engineered to minimise coding mistakes

- Fastest laser marking system with mark speed capability of up to 2,100 characters per second

- High-speed serialisation for pharmaceutical and tobacco applications, delivering unique and serialised codes at high production speeds

- Widest marking field reduces the number of lasers that are required to cover multi-lane / wide web applications, reducing investment and running cost

Laser Marking

- 7230 10-Watt and 7330 20-Watt fiber lasers for marking permanent quality codes on robust, high-density materials

- Light, compact and adaptable laser marking solutions offering high-speed marking, with complex data, easy operability and industry-leading integration capabilities

- Designed for demanding production schedules in the Parts-Marking, Food, Beverage, Consumer Packaged Goods (CPG) and Pharmaceutical industries

Laser Marking

- 50-Watt fiber laser marking high contrast at high speed

- Quality marking on robust plastic and metal materials

- Maximum single line speed: 440m/min (1440 ft/min)

Laser Marking

- 100-Watt fiber laser marking high contrast at high speed

- Quality marking on robust plastic and metal materials

- Maximum single line speed: 600m/min (1968 ft/min)