Flexible Films and Foils

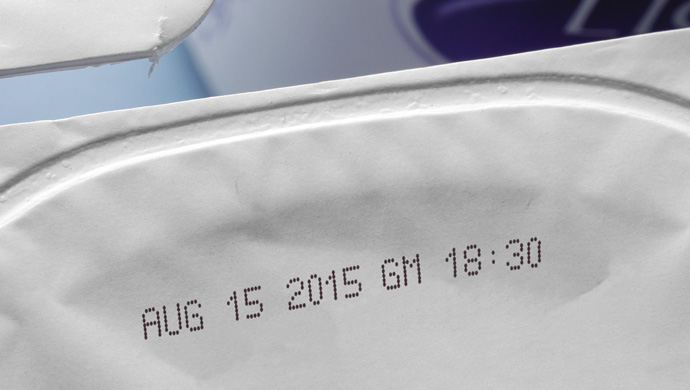

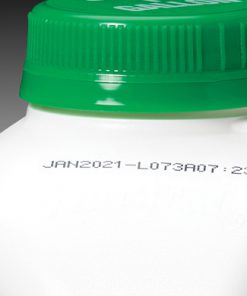

Industrial Coding and Marking Solutions for Flexible Packaging Printing

Low density polyethylene (LDPE) and flexible metallized films are widely used for confectionery and salty snacks packaging. Flexible packaging is the fastest growing packaging type driven by innovations including zippers, gussets and windows. Flexible packaging is also popular because of enhanced shelf appeal, portion control packaging and lower transportation costs.

Videojet Thermal Transfer Overprinters (TTO) deliver high resolution, variable data marks on a variety of film stocks with a selection of ribbon colors for added contrast. Continuous Inkjet (CIJ) printers can apply codes before or after the film is formed and packaged, offering integration options.

Continuous InkJet Printers Thermal Inkjet Printers Thermal Transfer Overprinters Laser Marking PrintersThermal Transfer Overprinters for printing on Flexible Films and Foils

- Intuitive tablet-like 5'' touchscreen controller with CLARiTY™ interface used in other Videojet technologies

- Simple cassette design holds 700m maximum of ribbon to allow for longer runs, and offers a safer and easier way to replenish ribbon, with minimal impact to production

- Code assurance comes as standard when using templates created by CLARiSOFT™ or VideojetConnect Design software

- Available with Bluetooth®* capability, allowing printer control via the Videojet 6230 App on an Android device**, rather than a HMI.

- Videojet iAssure™ intelligent technology which automatically detects common print defects, helping to reduce unwanted waste or reworked product

- Intelligent Motion™ technology removes the need for compressed air and associated costs and downtime, maximizing consistent print quality and printhead life

- Quick change printhead and minimal wear parts reduce the time production is interrupted when replacements are required

- Modular design that easily integrates into your production line and includes the option to mount the power supply and connection hub in the host machine control cabinet

Medium Duty Thermal Transfer Overprinters

- Videojet iAssure™ intelligent technology which automatically detects common print defects, helping to reduce unwanted waste or reworked product

- Intelligent Motion™ technology removes the need for compressed air and associated costs and downtime, maximizing consistent print quality and printhead life

- Quick change printhead and minimal wear parts reduce the time production is interrupted when replacements are required

- Modular design that easily integrates into your production line and includes the option to mount the power supply and connection hub in the host machine control cabinet

Laser Marking Printers for printing on Flexible Films and Foils

High Performance CO2

- 10W CO2 laser marking with CLARiTY™ touchscreen controller, engineered to minimize coding mistakes

- High performance delivers crisp codes on moderate line speed applications

- Line set-up wizard aids fast product changeovers, maximizing uptime

- Virtually no maintenance and limited consumables

High Performance CO2

- 30W CO2 laser marking with CLARiTY™ touchscreen controller, engineered to minimize coding mistakes

- Extended mark speed capability of up to 150,000 products per hour, ideal for high line speed applications

- High speed variable coding and data buffering, combined with the largest mark window in the industry, help increase throughput and performance

- Integration features for fast install and set-up

High Performance CO2

- 60W CO2 laser marking with optional CLARiTY™ touchscreen controller, engineered to minimise coding mistakes

- Fastest laser marking system with mark speed capability of up to 2,100 characters per second

- High-speed serialisation for pharmaceutical and tobacco applications, delivering unique and serialised codes at high production speeds

- Widest marking field reduces the number of lasers that are required to cover multi-lane / wide web applications, reducing investment and running cost

Laser Marking

- 7230 10-Watt and 7330 20-Watt fiber lasers for marking permanent quality codes on robust, high-density materials

- Light, compact and adaptable laser marking solutions offering high-speed marking, with complex data, easy operability and industry-leading integration capabilities

- Designed for demanding production schedules in the Parts-Marking, Food, Beverage, Consumer Packaged Goods (CPG) and Pharmaceutical industries

Laser Marking

- 50-Watt fiber laser marking high contrast at high speed

- Quality marking on robust plastic and metal materials

- Maximum single line speed: 440m/min (1440 ft/min)

Laser Marking

- 100-Watt fiber laser marking high contrast at high speed

- Quality marking on robust plastic and metal materials

- Maximum single line speed: 600m/min (1968 ft/min)