Case Coding and Labelling

- The Videojet 9560 PL is a reliable, automated pallet labeling system that reduces warehouse costs and mistakes

- Fully automated, it is specifically engineered to function in demanding conditions

- The 9560 PL can cover two or three sides and up to four labels, processing up to 120 pallets per hour across diverse applications

- To help ensure error-free operations, the system verifies label accuracy and reprints incorrect labels as needed

- The 9560 PL also interfaces with warehouse management systems and helps customers adhere to industry regulations

CLARiSUITE

Videojet’s CLARiSUITE Code Assurance Solutions help ensure that the correct code is applied in the correct location on the correct product and packaging.

Case Coding and Labelling

Large character marking (LCM) system The Videojet 2351 and 2361 high-resolution, large character inkjet cardboard box printers provide class-leading, consistent print quality on porous and secondary packaging materials. These systems are designed and manufactured to reliably print durable, high-quality codes, bar codes and graphics—even on extended runs—with minimal intervention. Available in a range of printhead heights to best suit your printing needs, the Videojet 2351 and 2361 inkjet box printers replace preprinted boxes and labels with a highly flexible, cost effective print-on-demand solution.

Laser Fume Extraction Systems and Filters

Fume extraction is an important element of any laser marking installation, helping to remove the smoke and particulate debris generated during the marking process. Fume extraction helps your operations by:

- Improving uptime by keeping your laser lens clean

- Maintaining safe operator working conditions

- Helping ensure product quality by keeping production lines clean

Laser Marking

2-Watt UV Industrial Laser Printer for High Contrast Marking on HDPE/LDPE

Laser Marking Systems The Videojet 7810 2-Watt UV laser marking system delivers high-contrast cold marking permanent codes enabling product lifetime track and trace for pharmaceutical, medical device and cosmetic manufacturers. Prevent the risk of counterfeiting and meet industry regulations with crisp, vision readable 2D codes on white HDPE and LDPE plastic, and other synthetic fiber materials such as DuPontTM Tyvek®. And with optional VideojetConnect™ Remote Service, your team can access Videojet experts to help improve productivity and troubleshoot potential issues in ways that other printers can’t.Laser Marking

Laser within Reach

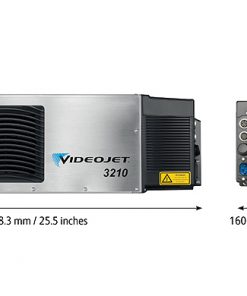

The Videojet 3210 CO2 laser removes the need to compromise on quality versus cost. Advanced German engineering and extensive laser application expertise are combined into a refined design that makes laser coding achievable for everyone.

Whether new to laser coding or upgrading from an older system, the 3210 is designed to make the transition seamless with a compact, single-box solution that is easy to install and requires minimal operator training. Laser systems offer unique benefits compared to traditional coding solutions. Featuring a long-life laser source, high-quality codes, and no consumables, the Videojet 3210 CO2 laser is an effective choice for your production.

High Performance CO2

- The 3350 is a connected solution with next-level flexibility, designed for seamless automated product changeovers

- With unparalleled digitally-enabled capabilities, this 30-watt CO2 laser is the ultimate solution for marking complex and high-quality codes at lightning-fast speeds in a range of industries including food, beverage, cosmetics, pharmaceutical, and extrusion.

- It allows for virtually unlimited font, code, and graphic options and boasts impressive line speeds of up to 900 m/min.

- Equipped with cutting-edge automatic and dynamic marking capabilities, the 3350 Smart Focus allows for seamless product changeovers without any manual intervention, thereby supporting your journey towards Industry 4.0.